The Ultimate Guide to Concrete Batching and Mixing Plants

Concrete batching and mixing plants play a crucial role in the construction industry by providing efficient and high-quality concrete production. These plants are a staple in the infrastructure sector and are essential for any construction project, big or small.

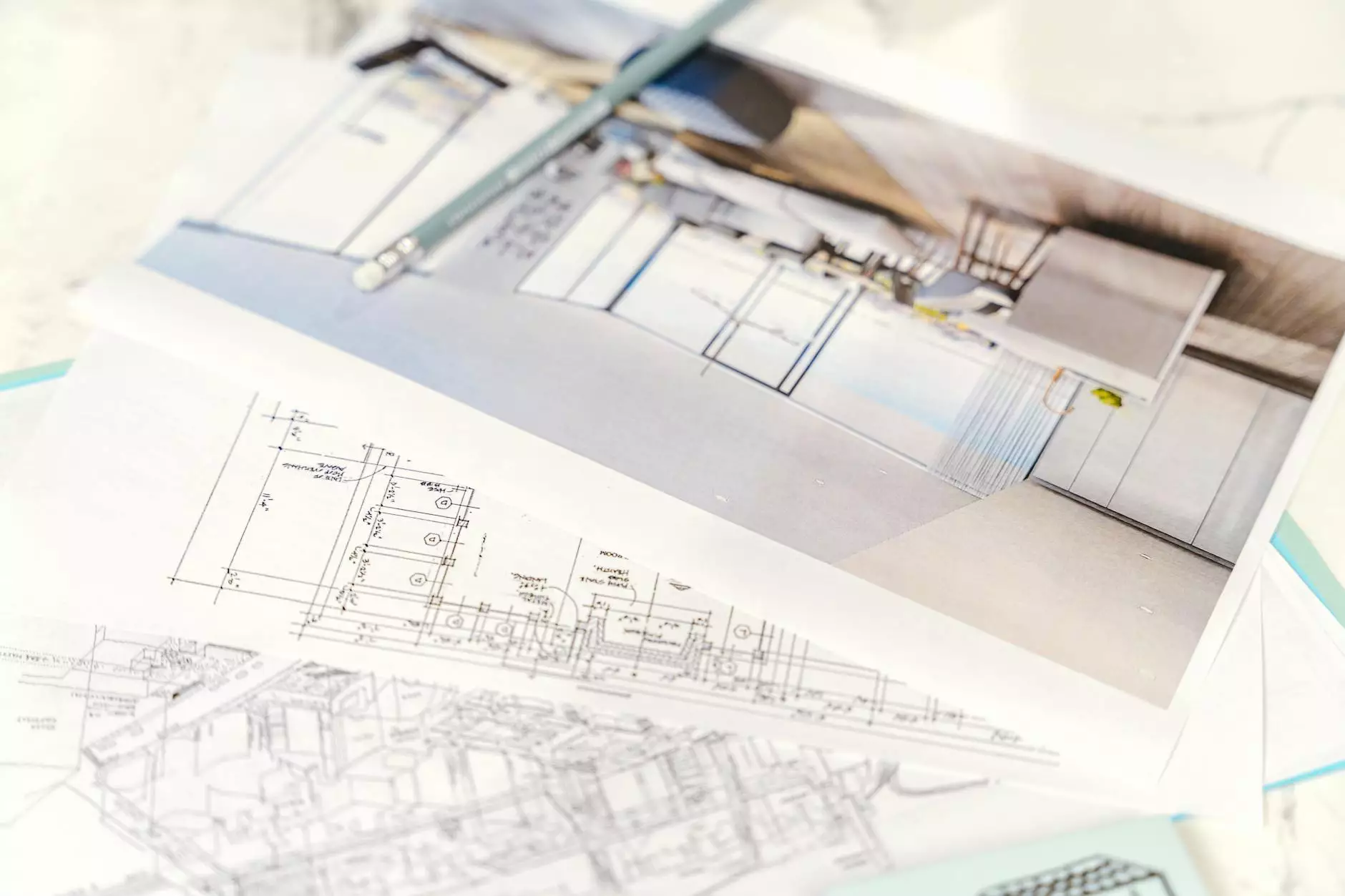

The Importance of Concrete Batching and Mixing Plants in Construction

Concrete batching and mixing plants are designed to mix various ingredients to make concrete, such as water, aggregate, cement, and additives. These plants ensure the consistent production of concrete in large quantities, meeting the specific requirements of construction projects.

Benefits of Using Concrete Batching and Mixing Plants

Efficiency: These plants are known for their efficiency in producing large volumes of concrete in a short amount of time, increasing productivity on construction sites.

Quality: With precise measurements and controlled mixing processes, concrete batching and mixing plants ensure high-quality concrete that meets industry standards.

Cost-Effectiveness: By reducing waste and optimizing resources, these plants help in cost savings for construction companies, making them a worthy investment.

Types of Concrete Batching and Mixing Plants

There are various types of concrete batching and mixing plants available in the market to cater to different construction needs:

- Stationary Concrete Batching Plants: These plants are set up at a fixed location and are ideal for long-term projects requiring consistent concrete production.

- Mobile Concrete Batching Plants: These plants are portable and can be easily transported to different job sites, offering flexibility and versatility.

- Compact Concrete Batching Plants: Designed for small to medium-scale projects, these plants are space-efficient and easy to operate.

Choosing the Right Concrete Batching and Mixing Plant

When selecting a concrete batching and mixing plant for your business, consider the following factors:

- Capacity: Determine the volume of concrete required for your projects to choose a plant that can meet your production needs.

- Features: Look for modern features such as automation, computerized control systems, and advanced mixing technologies for enhanced performance.

- Maintenance: Opt for plants that are easy to maintain and service to ensure continuous operation with minimal downtime.

Integration with Electronics and 3D Printing

Concrete batching and mixing plants can also be integrated with electronic systems and 3D printing technologies to further enhance efficiency and precision in concrete production. By leveraging these advanced technologies, construction companies can achieve superior results and stay ahead in the competitive industry.

Conclusion

In conclusion, concrete batching and mixing plants are indispensable for the construction sector, offering a host of benefits and efficiencies. By investing in the right plant and leveraging technological advancements, businesses can streamline their operations, improve concrete quality, and boost project outcomes.

For more information about concrete batching and mixing plants, visit polygonmach.com.